- View Mobile Number

- GST NO. : 27ABHPD3046P1ZG

About Us

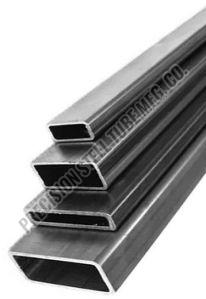

The distinctive characteristics of Precision Steel Tube Mfg. Co.’s philosophy and growth strategy that have set us ahead of its competitors are:

- Acquire and assimilate world class manufacturing technology.

- Strict adherence to quality standards.

- Rigorous application of metallurgical analysis and statistical process control techniques to ensure zero product nonconformity.

- Offer superior customer service for customer delight.

Customer focus - every customer is considered as the most important partner in the supply chain focusing not only on product aspects but also on ways and means to minimize their inventory costs through reliable, just in time distribution

We consider our associates as long-term partners in progress, be fair and transparent in our dealings with them and always honour our commitments. High quality, high technique and sincere service are the unchanged target that we aim at.

Our Vision

To provide products and services that meet or exceed our client’s expectations through innovation and constant improvement of our Quality Management Systems. We endeavor to have a strong and enduring relationship with our customers by providing best quality and services. We strive for excellence and is committed to offer the best possible products to all our esteemed customers by maintaining a progressive spirit and continuously developing technologies and solutions in keeping with the changes in times

Our Team

Our organization is backed by the team of the skilled personnel who are very efficient in their respective fields. They consistently work with the accuracy and dedication to produce wide gamut of tubes which are very well received by our clients. The team, which consists of Mechanical engineers, technicians, administrators and quality inspectors, consistently makes efforts to produce better and dimensionally precise customer require Training sessions and workshops are also conducted by us to update themselves with advanced technology and machines in the engineering industry.

Quality Control

The company adheres to stringent quality norms for all the processes. The materials used by PSTM are of very high quality and compatible to the latest machinery and production process. The company’s technical and commercial quality guidelines are set to high standards. A team supervises the quality assurance and control aspects along the entire process system by identifying and associating with the quality circle. Quality control tests are conducted regularly to maintain a uniform product quality.

Manufacturing Process

- The process of Tube Manufacturing starts with forming of CR/HR Steel strips into Tubular shape & welding the edges under pressure using high frequency induction heating.

- The basic raw material for manufacturing of pipes is CR/HR Coils.

- After receiving the raw material in Coil shape these are slitted into various widths according to requirements of tube diameter at Slitting machine.

- After slitting the slitted coil is loaded on the uncoiler and stored in accumulator to enable the continuous running of the mill while tail end of slit is welded with the leading end of next coil with the help of MIG welding

The strip is passed to a set of rolls to get the shape and the outer edges of strip are heated by high frequency induction coil. Outside flash of wielding is removed with the help of radius tool (Scarfing tool) so as to give better finish. The welded tube is again passed through a set of Rolls to get the specified tolerances on outside. After the pipes are made these are cut into the Required lengths with PLC Logistic Controls.

| Name of Founder | Mr. Mahavir Singh Dabaria |

| Year of Establishment | 1998 |

| Number of Employees | 50 - 100 |

| Nature of Business | Manufacturer, Supplier, Exporter |

| Market Covered | Worldwide |

| Legal Status of Firm | Individual (Sole proprietorship) |

| GST No | 27ABHPD3046P1ZG |

Contact Us

Precision Steel Tube Mfg. Co.

Plot No W-106/1, Additional MIDC, Anand Nagar, Ambernath East, Thane, Maharashtra - 421506, India

Call Us : View Mobile Number

E-mail : kunal.ranjan@precisionsteeltube.in